Maxillary Overdenture with Ceka Revax Attachments Supported by Branemark System Implants

The Ceka Revax system contains all of the components needed to produce a successful fixed/detachable overdenture. The proven record and long-term use of this attachment in the dental field makes it a familiar and viable treatment plan. The Revax system has a complete accessary armamentarium for the replacement and maintenance procedures.

The attachment from the factory has 830 grams of retentative force which can be adjusted upon patient request. This retention is well above the minimum of 400 gms per attachment advocated by Lehmann and Arnin.

The overall size of the Revax (3.8 mm high and 3.4 mm wide) allows the restoration to remain within normal parameters. When the Revax is used in a substructure bar with a precision milled design, increased lateral stability is achieved.

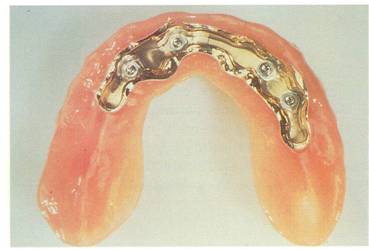

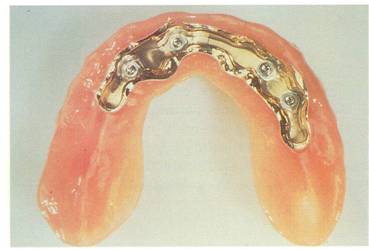

The strength and durability of the over denture is increased when a metal backbone or superstructure is incorporated in the prosthesis as in Figure 5-21. The Revax is available in four al_oys for casting with virtually any metal.

The male attachment is preserved during processing through the use of duplicate processing pieces. After processing, finishing, and polishing, Ceka-Bond cement should be applied to the male threads before they are screwed into the female. This prevents the male spring pin from unthreading during function. However, the male spring pin may still be removed at any time using the special tool.

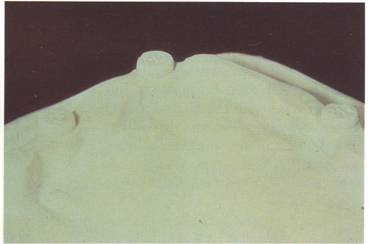

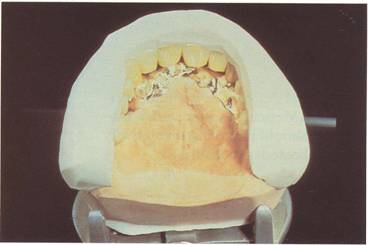

This maxillary bite rim has incor-porated Branemark System impression copings. The design is both implant and tissue borne.

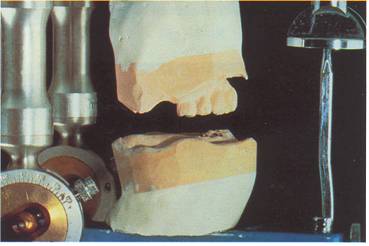

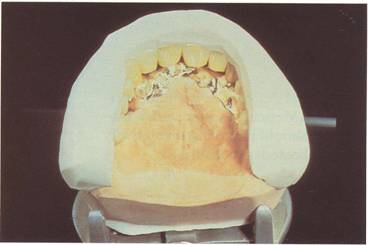

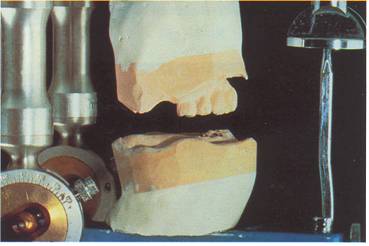

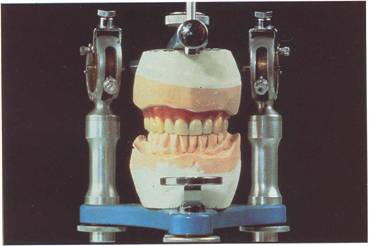

Side view of mounted casts illustrates the amount. of labial ridge and tooth contour that must be restored to produce a true skeletal Class I occlusal scheme.

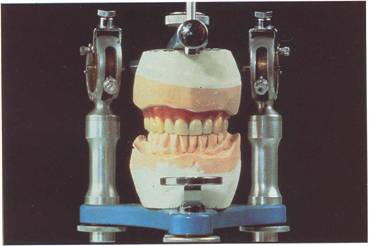

Teeth are selected (Vita Lumin Acryl) and set up in Class I position for a diagnostic evaluation.

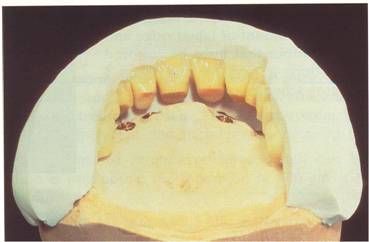

The master cast is indexed, lubri-cated, and a silicone matrix (Nobcl-pharma) applied.

All pink wax is steam cleaned away. The master cast supports matrix with teeth held in setup position.

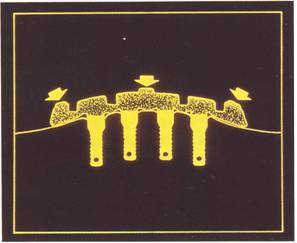

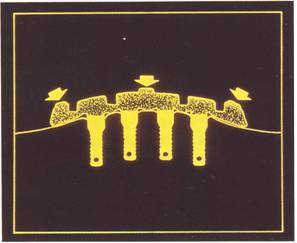

This diagram shows the implants and the proposed design of the substructure bar with Revax-retained overdenture.

The arrows pointing at the bar indicate raised milled platforms. This design allows room for attachment function and supports vertical forces with the tripod effect. The four recessed slots on the top of the bar represent the Revax finale patterns.

The entire bar pattern must combine all attachments, raised platforms and exterior surfaces into a precision milled path of insertion.

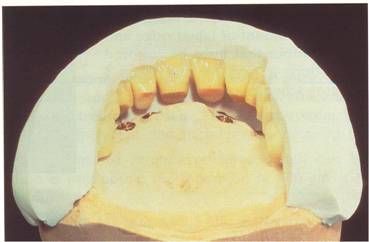

The matrix is checked on the master cast. Teeth are ground out to make room for the bar attachment.

A bar is fabricated using castable plastic cylinders and self-cure resin. The Revax females are positioned with a paralleling mandril in arrangement with the path of insertion and secured with resin.

In this occlusal view of the completed substructure bar pattern, the spruing, investing and casting techniques all follow the protocol.

Cast cylinders are protected during all finishing and polishing procedures with metal protective caps.

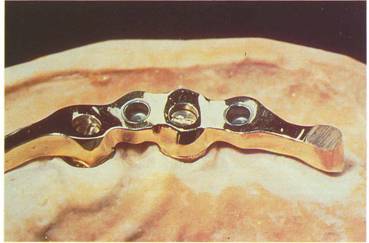

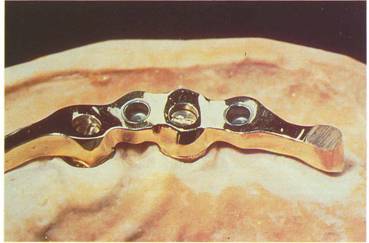

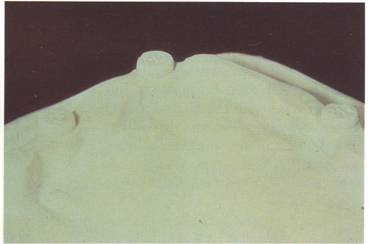

The finished and polished bar is secured to the master cast with gold screws. Note the Revax females, distal platform, and parallel lingual wall.

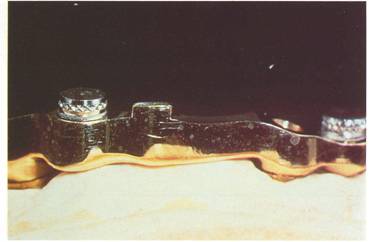

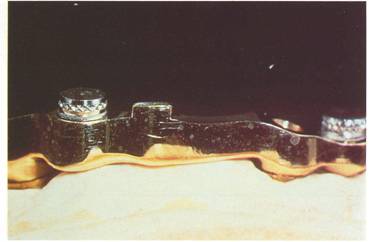

A labial view of the gold bar with Revax males in place.

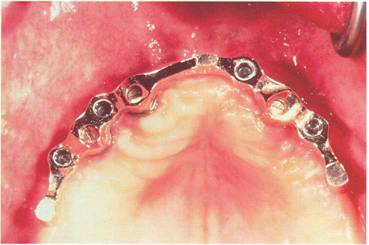

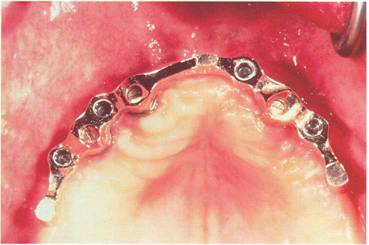

An intraoral view of the substructure bar try-in.

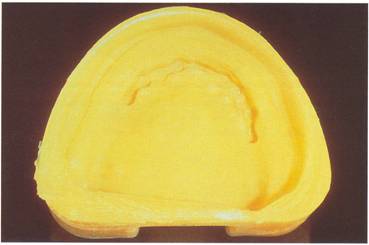

The lubricated bar is shown with processing pieces in place over a silicone blockout. The red outline on the cast indicates the proposed border of the blockout material.

An impression is taken of the entire cast with bar. A refractory model is then poured.

The superstructure pattern is created on the refractory cast. Care is taken to keep the pattern thin in areas contacting the teeth in the matrix. The cast with completed pattern is sprued, invested, burned out, and cast in a type IV gold alloy.

The casting is devested, cleaned, and finished. All areas that have tissue contact are highly polished.

The overcasting is fitted to the bar on the master cast and checked with the tooth matrix. All final adjustments in the metal frame and acrylic teeth are made at this time.

Using the matrix, denture teeth are luted to the overcasting and master cast. Peripheral borders are finished in wax, with the lingual aspect in a horseshoe design. Investing, processing and finishing techniques are completed. With care, the master cast can be preserved.

The occlusal view shows the finished prosthesis with polished rugae adding to the correct anatomical features.

The final delivery of bar and over-denture. Meticulous laboratory fab-rication should make this a relatively uncomplicated procedure.

The labial flange effectively masks the metal bar. Correct selection and placement of teeth combine to make this a very esthetic restoration.