Lingual technique

Fixed appliances can be positioned lingually when the design of the lingual brackets is adapted to the oral conditions. The height of the brackets with adhesive base, bracket body, slots, and wings and the distance of the archwire from the tooth surface determine wearing comfort or can cause speech restriction or tongue irritation. The appliance must therefore have a very flat design.

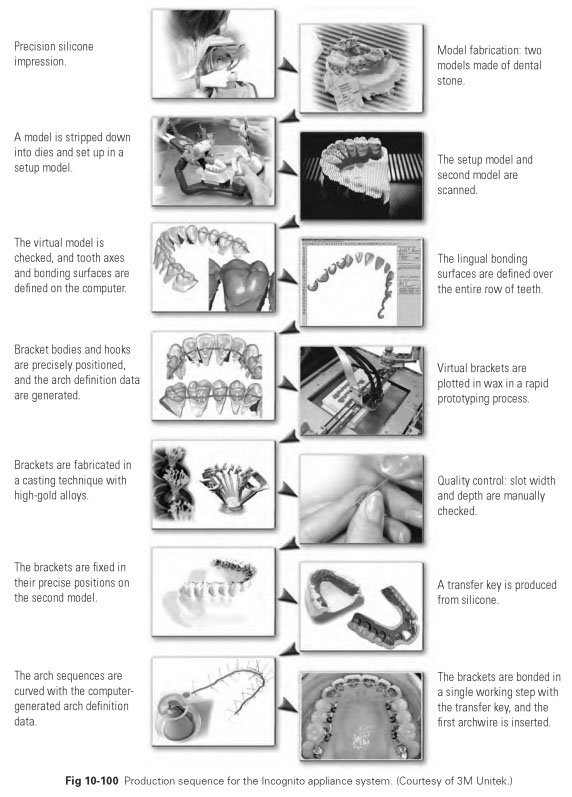

In the Incognito appliance system from 3M Uni-tek, a computerized production process is used to customize and position the brackets for the individual patient. A precision silicone impression is first taken. The silicone impression must be completely bubble-free. Teeth and the whole gingival margin must be precisely recorded in the impression so that the tooth axes can be accurately defined.

Two dental stone models are prepared. In one model, the teeth are sawn out and set up in the ideal occlusal position intended at the end of treatment. This setup is then digitalized with a 3D scanner to produce a precise, virtual 3D model.

Based on this virtual model, a customized set of brackets for the individual patient is generated on the computer with special software. Appropriate bonding sites on the lingual surfaces are first shaped, then the optimal positioning of the bracket bodies is determined. The individualized base of the bracket covers the greater part of the lingual surface with good accuracy of fit, which makes it much easier to carry out precise positioning and any rebonding that may be required.

After the individual components (base, bracket body, hook) have been precisely positioned on the screen, the rapid prototyping process takes place as the virtual brackets are converted into wax. Final completion can be done by precision casting with high-gold alloys. Thereafter, the correct dimensions of the slots for each bracket are checked by hand.The diameters of the arches and the slot sizes are perfectly harmonized with each other with variations of not more than 0.008 mm between slot and arch. Relative movements between the two parts—to the detriment of correction accuracy—are virtually ruled out.

The finished gold brackets are positioned and temporarily bonded onto the second dental stone model. From this situation of accurately positioned brackets, a silicone impression is taken in which the brackets are definitively fixed. The bonding surfaces of the brackets in the impression are pretreated for bonding to the tooth surfaces. The orthodontist can use this silicone key to fix all the brackets to the lingual surfaces with a special bonding agent in one operation. The brackets are then in the precise position that was predefined in the laboratory.

The arch definition data are generated at the same time as the virtual construction of the brackets and help to produce an arch sequence involving several archwires. The course of the arch is defined virtually on the computer and related to the position of the brackets. Highly complex bends result from the individual course of the arch, and these bends are made with a computer-controlled machine.The arch runs parallel and fits very closely to the tooth surfaces.

The inserted wire is shaped so that it pushes the teeth into the correct position during the course of treatment.

The regulating thrusts are performed by using elastics with the archwire. Insertion of the wires into the slots (ligation) is done with rubber link chains or wire ligatures that fix the wire very tightly in the slot.The regulating thrust arises from the differently sized archwires.The initial thermoelastic wires recover from their bending once they are at oral temperature and, in so doing, pull the tooth that is bodily clasped via the bracket.

These superelastic arches are used at the start of treatment to resolve malpositions. Later, nonsuperelastic (plastic deformable) arches are used that develop differing recovery forces due to different cross sections.

The advantages of the Incognito appliance system are the following:

- Accurate, arch-guided transfer of forces

- Adaptation of the brackets, even in cases of severe rotation and short clinical crowns

- Flexible, universal usability due to customized sets of brackets

- Esthetically highly advantageous

Figure 10-100 illustrates the production sequence for the Incognito appliance system.