Retentive components of an active plate

The clamping effect holds the active plate in the mouth until the teeth are tipped; once the remodeling processes commence, the clamping effect subsides. Additional retentive components are therefore necessary. Spring components that perform corrective functions cannot be used as retentive components. Because the spring force can only be as great as the normal clamping force of the baseplate, its effect will decline after the appliance has been worn for a short period of time.

Retentive components are clasps whose spring action only starts once they are moved out of their resting position. They are guided into the undercut areas of the teeth; they engage vestibularly, lie mainly pressure-free, and use the baseplate margin as their abutment. Retentive components may only be used indirectly for tooth movement when, fixed to the baseplate, they are moved along with the baseplate. Retentive components have to participate in orthodontic tooth movements without loss of anchorage. After tooth movements have been achieved and after tooth growth, the position of the retentive components must be corrected. Retentive components are bent out of hard, round steel wire with a diameter of 0.5 to 0.7 mm. Thin wire is necessary because the retentive components are always guided in a vestibular direction over the closed dentition.

It is essential to ensure that retentive components exert no regulating effects. This is why the clasps only have punctiform contact with the teeth below the bulbous part of the tooth. If the clasps had linear contact, corrective treatment might activate orthodontic forces acting on the retaining teeth. With punctiform contacts, it is much easier to make a correction, especially when several teeth are incorporated with a closed wire band.

Four types of clasp (or crib) with different modifications are used as retentive components: (1) Adams clasp, (2) eyelet or triangle (delta) clasp, (3) ball clasp, and (4) arrowhead clasp.

Other types of clasp are possible, and their value depends on how well they fulfill their retaining function without being the source of uncontrolled orthodontic forces.

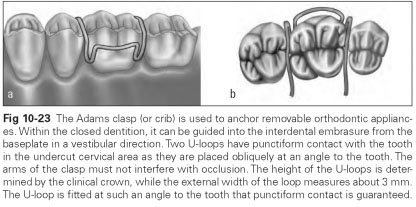

The Adams clasp enables the baseplate to be fixed to a single tooth, for which the maxillary posterior teeth are best suited. Mandibular posterior teeth are often still too short and hence have no undercut areas buccally. Therefore, the possibility of trimming the gingiva on the model until the necessary undercuts are exposed may be considered.

The Adams clasp is a closed clasp with two U-shaped loops guided over the tooth at an acute angle (Fig 10-23). The tips of the loops (called the arrowhead) contact the tooth close to the interdental papillae in a buccal-approximal position. The buccal bar runs horizontally at a small distance from the tooth so that bending open or tightening the horizontal part can bring the loops closer together or move them further apart. If the U-loops are bent too acutely in relation to the tooth, the plate will be levered off. It is of primary importance, however, to avoid linear contact.Two crosspieces (known as "ears" or "arms") run interdentally over the dentition to the appliance baseplate, where they are anchored via relatively long retentive tails. The arms must not interfere with occlusion if the plate has no posterior occlusal planes.

The baseplate margin and Adams clasp engage the tooth on all sides; this means that bodily tooth movement can be initiated when the part of the baseplate with the Adams clasp is moved by a screw. So that the Adams clasp cannot bend out of shape, the parts extending transversally over the teeth can be reinforced by spikes.

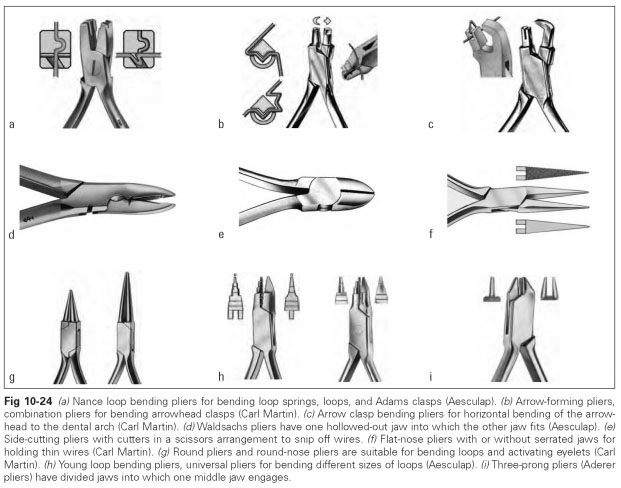

An Adams clasp is fabricated from bent 0.7-mm spring hard wire or from semifinished parts. Flat-nose pliers and flat pointed pliers are required. (Figure 10-24 illustrates several types of wire-bending pliers and their specific indications.) First the length is transferred from the tooth to the horizontal buccal bar, and the ends of the wire are bent at right angles.The U-loops are then bent with the flat pointed pliers. The height corresponds to tooth height, and the maximum width is 3 mm.

The U-loops are bent at an angle of 45 degrees to the horizontal buccal bar, and the arms are guided interdentally over the dentition. The buccal bar must be adapted to the tooth contour. In the mandible, it will become necessary to place an occlusal rest on the middle of the tooth, starting from the lingual, so that the plate does not sink down to the floor of the mouth.

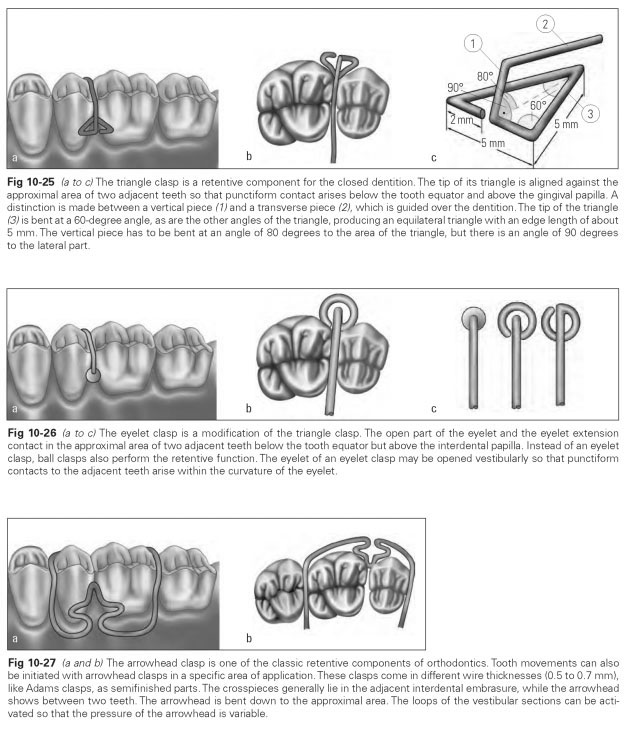

Triangle (or eyelet) clasps lie with the tip of their triangle or their eyelet curvature against the approximal area of two adjacent teeth, below the tooth equator but above the interdental papilla (Fig 10-25). They have only one arm running over the dentition. This type of clasp is bent out of 0.7-mm spring hard steel wire. The triangle is designed in accordance with the size and shape of the interdental space between the anchoring teeth. The triangle may be an equilateral triangle with a side length of 5 mm, while the eyelet, a modification of the triangle clasp, has a diameter of about 3 mm. The crosspiece of the clasp is laid over the dentition in the interdental embrasure and, with a retention arm, extends into the baseplate of the appliance.The relatively long crosspiece readily bends out of shape and therefore often has to be corrected, which damages the material. The clasps can break, be swallowed, or be aspirated into the trachea. In view of this notable disadvantage, arrowhead clasps tend to be preferred, or triangle clasps are only used temporarily.

The difference in application between eyelet and triangle clasps may be that triangle clasps extending into the interdental spaces could also be used as space maintainers, especially since the free triangular bracket can be activated for horizontal thrust. This jeopardizes the spring and clasp function because of the weak crosspiece. Eyelet clasps can be used as a technically simple retentive component.

The ball clasp is an eyelet clasp reduced to a ball (or droplet) in the actual area of retention (Fig 10-26). In the past, the ball used to be formed from a drop of solder at the end of the wire. Today it is used as a semifinished part and is made of 0.5- to 0.7-mm wire. The ball lies firmly in the interdental area, with the crosspiece guided over the dentition, and is sensitive to warping and can break after multiple corrections. To achieve an adequate length of spring arm, the crosspiece is lengthened in the vestibular direction, and the ball is placed in an arc in the interdental area of retention.

An arrowhead clasp, like an Adams clasp, has two arms that lie over the closed dentition (Fig 10-27). An arrow-shaped loop is formed, the arrowhead being bent toward the interdental retention area of two teeth. The long wire loops from the arms (as far as the arrow) run at a distance of about 1 mm from the gingiva and ensure that the arrowhead has a wide spring deflection.

The arrowhead contacts two teeth and can be worked with a certain pretension; the outer support is the edge of the baseplate. As the arrowhead contacts the tooth below its equator and in the process exerts some pressure, tooth growth is supported rather than impeded.This is reinforced by the fact that the arms do not run in the interdental embrasures of the anchoring teeth but at a distance from them in the approximal area of other teeth. Hence the arrowhead clasp can be used to a limited extent for single-tooth movement by shaping just half an arrowhead that only contacts one tooth and moves it.

Where a plate is normally anchored, two arrows are used in one loop unit per half jaw. If firmer retention is required, three arrows can be fitted into the interdental spaces as a loop unit for each half of the jaw. However, the longer the loop unit, the weaker the clasp structure will be.

An arrowhead clasp is bent out of 0.7-mm spring hard clasp wire; arrow-forming pliers and arrow clasp bending pliers are recommended for shaping the arrows according to a specific bending sequence.

Clasp forms taken from prosthodontics transfer uncontrolled forces due to linear contact, so they should not be used for orthodontic purposes.

The C-clasp (circumferential clasp) is a singlearm clasp made of 0.7-mm spring hard wire shaped into a small eyelet at the clasp tip. It runs from just above the gingival margin in a vestibular direction around the tooth.